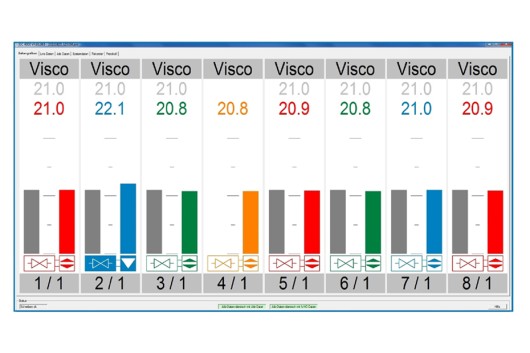

Viscosity Measurement & Control

Ink Pumps, Sensors, Coatings, Software, Viscometers

All viscometers, regardless of their design, will work, but choosing the correct device that will best function in your production environment, is the key. Whether the printing process is flexographic, gravure, offset, or there are applications related to coating and spraying within the chemical, food or oil industry, we offer solutions for automation and controlling parameters of liquids in production processes, as well as instruments to measure, handle and control liquids and dosing equipment for liquid components.

Jenton are proud to have been distributors for opti-color™ viscosity control systems since the 1970s. Viscosity control of inks, coatings and other liquids will optimise the use of expensive pigments relative to diluents but, most importantly, will ensure consistency of product appearance and performance.

opti-color’s main products feature Viscosity Measurement and Control units, conditioning (heating, cooling) and circulation systems that range from manual Viscosity Test Cups relative to size, design and speed, to automatic Viscosity Control and measurement systems. These include rotational or Falling Ball Sensors, OBD Sensors and Viscosity Software.